Sinoflo ESP Factory-6 Workshop Sections Establishment

Sinoflo ESP (Electrical Submersible Pump) factory has established six workshop sections for stator lamination, stator winding embedding, motor assembly, pump assembly, protector assembly, and separator assembly. At present, it has formed an annual production capacity of 1,150 sets of ESP.

Now, 23 series and 550 types of ESP have already been successfully put into production.

TM375, 456, 540, 562, 738 series submersible motor;

TPR338, 400, 513, 675 series protector;

TS338, 400, 513 series separator;

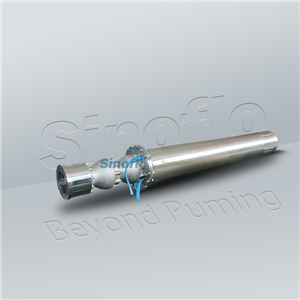

TIN338, 400, 513, 675 series intake;

TP338, 400, 513, 675 series submersible pump;

Complete range: motor, protector, separator/intake, pump, MLE, power cable, control cabinet, wellhead device, downhole accessories, downhole tools.

Application range: ambient temperature 90~260°C, Maximum head: 5000m, capacity: 3000m3/d. The ESP is widely used in offshore and onshore oil extraction, geothermal water, ultra-high head groundwater and small-bore mountain well lifting project, underground brine and other corrosion fluid Extraction works.

Upgrade of Submersible Electric Pump Manufacturing Technology

Upgrade of Submersible Electric Pump Manufacturing Technology:

High-efficiency, wide channel impeller

High load thrust bearing

Sand-proof electric pump

Anticorrosive electric pump

High temperature resistant electric pump

Capacity expansion motor

Sinoflo continuously expands its product range in the submersible electric pump product field, and high-tech technology throughout the whole series, leading Sinoflo ESP and submersible pumps to reach the world's advanced high-quality ranks. We firmly believe that Sinoflo electric pump technology will continue to improve Efficiency of existing production.