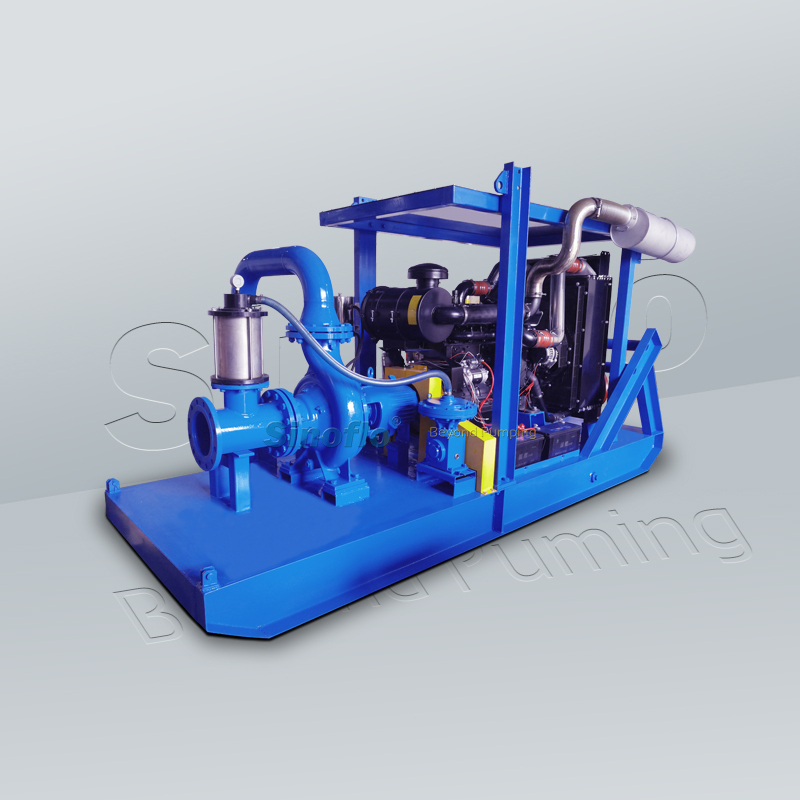

Non-clogging Self-priming Sewage Pump

- Sinoflo

- China

- 15-30days as per different pump material

-King of self-priming sewage pumps;

-Flood control;

-Non-clogging design, open impeller structure;

-Flow range: 10 ~750m3/h;

-Head range: 3~38m;

General Introduction

Sinoflo non-clogging self-priming sewage pump is suitable for municipal sewage and industrial wastewater treatment projects, as well as various wastewater classification treatment and centralized treatment systems. It is known as the "king of self-priming sewage pumps" and is the most ideal new generation of sewage pump products.

Feature

Stable performance and reliable use;

Fast self-priming and high suction;

Back-pull-out structure: easy maintenance and troubleshooting. Only common tools are needed for quick and complete routine maintenance, saving time and effort;

Open impeller structure, non-clogging design, strong passing capacity;

Easy to use: just install the pump on the side of the sump and stick the suction pipe into the liquid level to work. (The pump needs to be filled with water for first time start.)

Operation Conditions

Liquid temperature: 0°C ~40°C, medium density: 1.2x103kg/m3, PH5~9;

The volume ratio of solids: ≤2%;

Maximum particle diameter: SP-2 (38mm), SP-3 (53mm), SP-4/6/8/10 (76mm);

Ambient temperature: ≤40°C, altitude: up to 1000m;

Flow range: 10 ~750m3/h;

Head range: 3~38m;

Power range: 1.1~90kW;

Application

Non-flammable and explosive liquids;

Rainwater and general sewage;

Municipal sewage works, construction sites, civil air defense system drainage stations;

Industrial wastewater such as light industry, papermaking, textile, food, chemical industry, electricity, mining, etc.;

Sewage discharge in residential areas;

Sewage and sediment from the water purification system;

Tanning industry, slaughterhouse sewage, river pond breeding industry;

Wine industry and sugar industry;

Discharge of sewage that is not highly corrosive but has been seriously polluted;

Installation Condition

The suction pipe can be soft and hard type. The material of the pipeline must be suitable for the pumped liquid, and the hose must have sufficient rigidity to prevent the suction pipe from being deflated;

The suction pipe should be kept as short and straight as possible, and less elbows and accessories should be used, and elbows with larger radius should be used.

The distance between the suction pipe immersed in the sump and the pit wall should be greater than 1.5 times the pipe diameter. The suction pipe must not be installed near the water flow (there may be a vortex), otherwise, a baffle should be added between the suction pipe and the water flow, with a distance of 1.5 times the pipe diameter.

If there are more than two suction pipes in the same sump, the distance between the pipes should be greater than 3 times the pipe diameter.

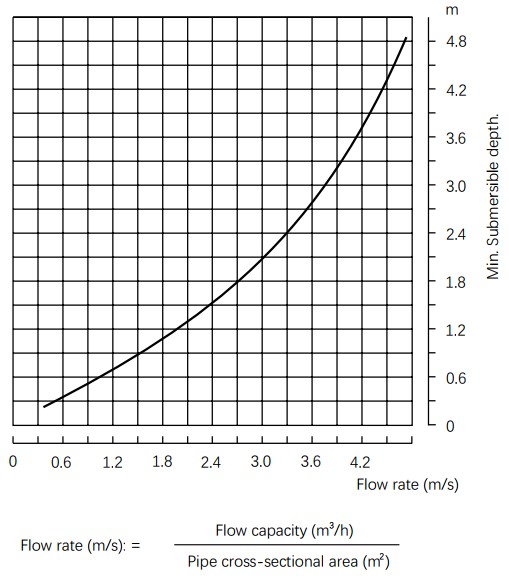

Suction pipe immersion depth:

-The immersion depth of the suction pipe is related to the liquid flow rate in the suction pipe

(see Figure 1).

-The immersion depth of the suction pipe can be reduced by expanding the diameter of the suction pipe and reducing the flow rate of the influent water.

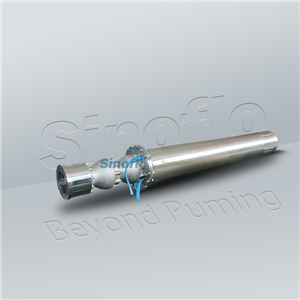

-Increase the suction pipe diameter by installing a standard reducer.

-Concentric reducers are used for vertical expansion.

-Horizontal expansion adopts eccentric reducer.

-It is recommended to expand the suction pipe diameter ratio by 1.3~1.5 times the pipe diameter

In flooding status (pump has inlet pressure), the inlet pressure should not be greater than 50% of the maximum allowable working pressure.

If the pump is equipped with a filter screen, the flow area of the filter screen is 4-6 times the flow area of the suction pipe, and the maximum particle diameter of the filter screen is guaranteed to be smaller than the maximum particle diameter of the pump.

Figure 1

Recommended Suction Pipe Immersion Depth vs Flow Rate

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more