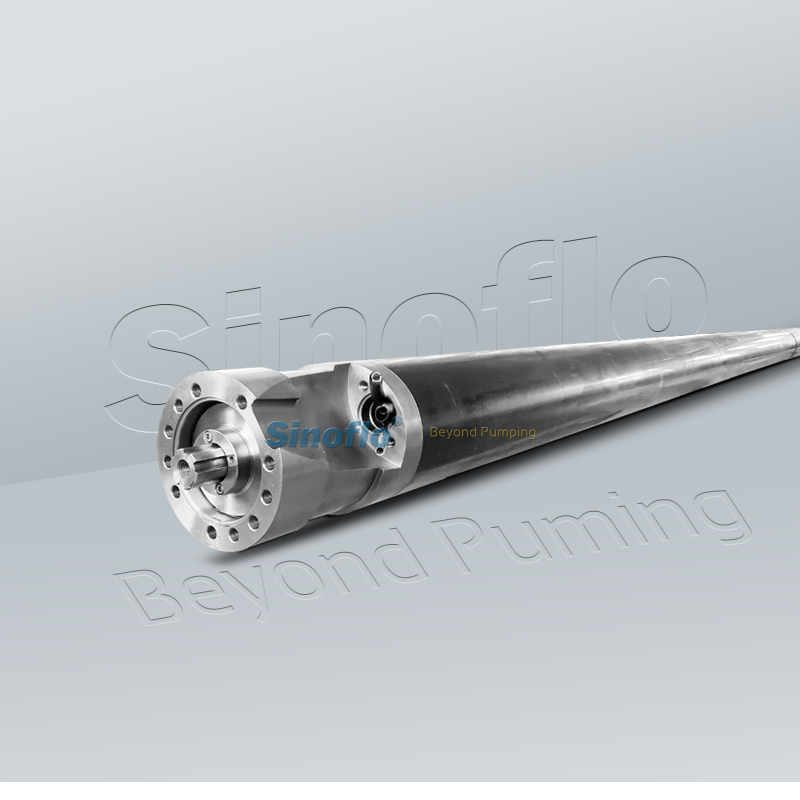

Electric Submersible Progressing Cavity Pump

- Sinoflo

- China

- 15-30days as per different pump material

338/387/400/540/538/562/675 series ESP:

-Computer-aided 3D design;

-Floating, semi-floating and fully compressed structure and sand control and anti-corrosion design;

-Precision casting impeller and casing with nickel-containing material;

-Monel K-500 high strength shaft

-Anti-wear gasket is made of CEF phenolic cloth material

Product Overview

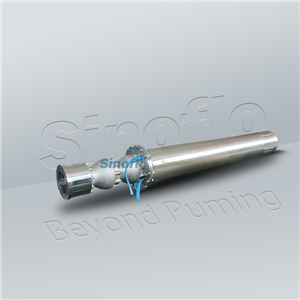

Sinoflo Electric Submersible Progressing Cavity Pump (ESPCP) fundamentally eliminates the problem of rod screw pump such as; the rod broke and limited by the deep and deviated wells. it also overcome the problem that the pump efficiency is low when the pump transports viscosity crude. For ESPCP has no valve body and complex runner, little hydraulic loss, sucks and exhausts medium continually, uneasy to be blocked by sand and gas lock, so the fluid transported by pump has wide range which includes high viscosity, high wax content oil, sand or gas content oil.

Feature

Suitable for pumping high viscosity fluid and solids fluid;

Anti-gas locking and demulsifying;

The pumping process is continuous and stable;

Suitable for vertical, deviating, horizontal well, specially suitable for the well which has the sucker rod scrubbed the tube;

NO sucker rod, to eliminate the loss caused by the rod wear;

Working Condition

Ambient medium temperature: ≤150°C; Oil well temperature: 50~180°C. When the temperature is less than 90°C, for O-ring generally use nitrile rubber; for thrust washer on the impeller, the phenolic laminated board is generally used; While if the oil well is higher than 90 °C, for O-ring, generally use fluorine rubber (170°C) ), the thrust washer on the impeller generally use F4 polystyrene (150°C);

Gas content: The submersible pump is completely submerged into the well fluid when it is working in the well. Oil wells often contain different kinds of free gases, which will have a serious impact on the working performance of submersible pumps. When it reaches to a certain amount, it will cause air lock. Gas interference seriously affects the normal operation of submersible electric pumps, causing the motor load to change drastically or unloading, the oil separator can be installed under the submersible pump;

Sand content of well fluid: ≤0.05%;

Applicable medium: oil-water or mixture of oil & gas and water;

Well fluid viscosity: ≤7mm2/s;

Advantages

Large capacity is the main advantage of this oil recovery ESPCP. However, current ESP CPsubmersible electric pumps are also frequently used in oil wells with relatively low oil production.

This ESPCP is capable of transferring water from the upper water layer in the well to the lower water injection layer.

Simple operation, convenient management;

Applicable in inclined wells, horizontal wells and offshore oil production.

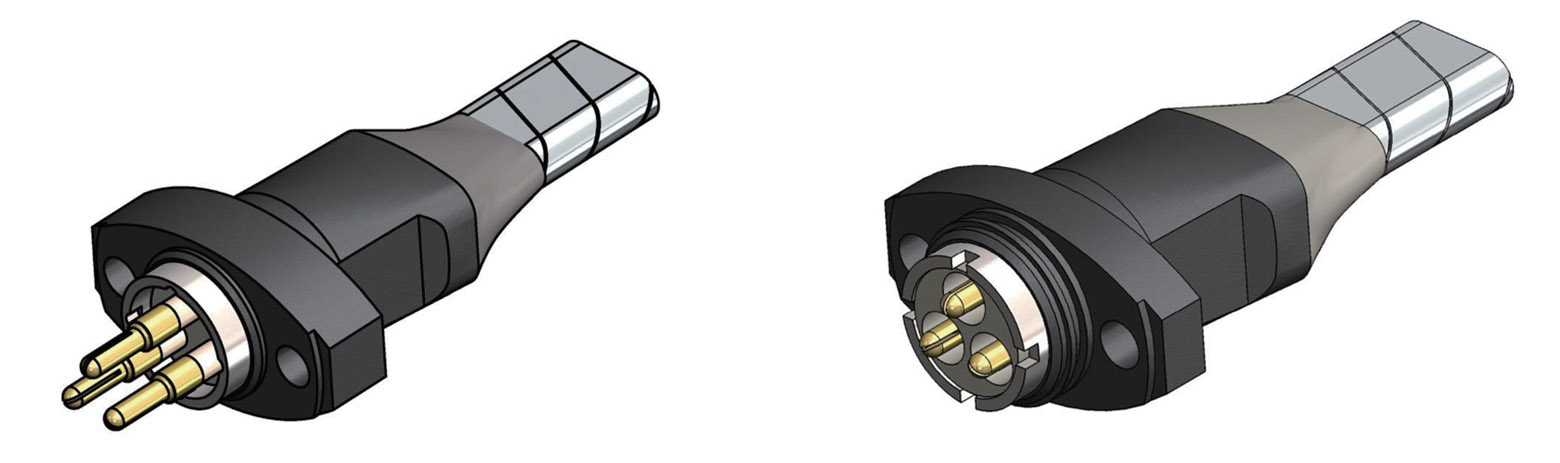

Easy to install downhole pressure and temperature measure equipment, and the related measuring signal can be read on the ground transmitted by the cable.

In order to adapt to the decline or change of oil well production, the frequency conversion device can be used to adjust the power frequency to meet the requirement;

Longer maintenance period, and the oil production time of oil wells is relatively high.

Technical Parameter

Flow capacity: 6.4~103m3/d;

Head: 550~1800m;

Max. O.D: 89.5~114mm;

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more