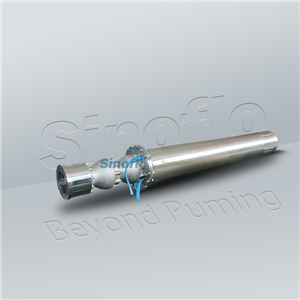

Metallic Diaphragm Pump

- Sinoflo

- China

- 15-30days as per different pump material

Technical Parameter:

-Max. particle size: 6mm;

-Max. flow capacity: 50m3/h;

-Max. head: 84m;

-Max. air supply pressure: 8.4bar;

-Max. self-priming: 8m;

-Inlet/outlet diameter: φ10mm (3/8"), φ15mm (1/2"), φ25mm (1"), φ40mm (11/2"), φ50mm (2"), φ65mm (21/2"), φ80mm (3"), φ100mm (4");

Product Overview

Sinoflo Pneumatic Metallic Diaphragm Pump adopts two kinds of inlet & outlet connection: flange connection and internal thread connection, which is convenient for customers' needs.

Imported diaphragm materials guarantee for a longer service life;

The ball is further processed with higher roundness, improving check valve sealing performance;

The mounting bolts are all made of stainless steel, which is sturdy and durable and not easy to rot;

The new type of pilot valve has low air consumption and low daily use cost;

Small size, can be used in a variety of occasions, easy to install;

Dry run operation available without any damage;

No lubrication required;

Technical Parameter

Max. particle size: 6mm;

Max. flow capacity: 50m3/h;

Max. head: 84m;

Max. air supply pressure: 8.4bar;

Max. self-priming: 8m;

Inlet/outlet diameter: φ10mm (3/8"), φ15mm (1/2"), φ25mm (1"), φ40mm (11/2"), φ50mm (2"), φ65mm (21/2"), φ80mm (3"), φ100mm (4");

Material

Body: S.S304/316/316L, Aluminum, etc;

Diaphragm: Santoprene®(SP), Hytrel (HY), Viton (VT), PTFE, EPDM, Buna-N (BN); Neoprene (CR)

Ball Valve: Teflon (TF), EPDM, BN, S.S, Santoprene®(SP), HY, VT, PP;

Valve Seat: PTFE, PVDF, AC, Santoprene®(SP), HY, VT, PP;

Valve Seat: PP, S.S, Al.

Differences of Plastic Diaphragm Pump and Stainless-Steel Diaphragm Pump

Weight: plastic diaphragm pumps are lighter, while stainless steel diaphragm pumps are heavier. The obvious reason is because the materials are different;

Use Scope: plastic diaphragm pump can basically transport a part of the organic solvent. Stainless steel diaphragm pump has poor corrosion resistance to acidic media, and most of them are used for highly viscous, volatile, flammable and highly toxic liquids. Compared to stainless steel diaphragm pump, plastic diaphragm pump can transport acidic liquids. Because acid is very corrosive to metals. Where the conditions are not meet to use S.S diaphragm pumps, then plastic pumps can be used. This is big advantage of plastic diaphragm pump that differs from stainless steel diaphragm pump;

Liquid Temperature: plastic diaphragm pump could transport liquid not higher than 80oC, and stainless-steel diaphragm pump can transport liquid around 120oC;

Physical Strength: plastic diaphragm pump is slightly lower, while stainless-steel diaphragm pump is stronger;

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more